Industry information

Company News

- The modern aesthetic journey behind aluminum veneer

- Aluminum alloy air conditioning cover: In summer at home, it's even cooler!

- Aluminum veneer: a modern interpretation of architectural aesthetics

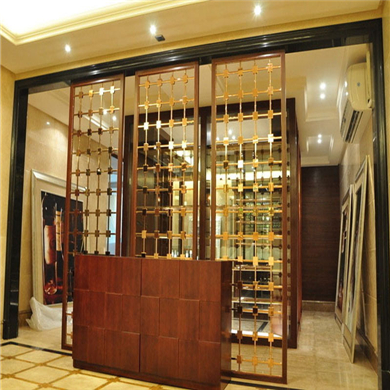

- Aluminum veneer customization, creating a new choice for personalized space!

- Aluminum veneer decoration is a new trend, with a light luxury texture that can be reached at a touch!

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization: an artistic journey to create personalized spaces

- A new choice for 2.0mm aluminum veneer wall decoration

- Aluminum alloy air conditioning cover: the guardian of the new fashion of summer home furnishings

- Application fields and effect display of carved ceiling aluminum veneer

Frequently asked questions

- What is the production process of aluminum veneer?

- What will be the future innovation and development trend of aluminum veneer?

- What are the unique advantages and characteristics of aluminum veneer?

- What is the environmental performance of aluminum veneer? Does it meet the requirements of current sustainable development?

- What are the unique design and application advantages of aluminum veneer curtain walls?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

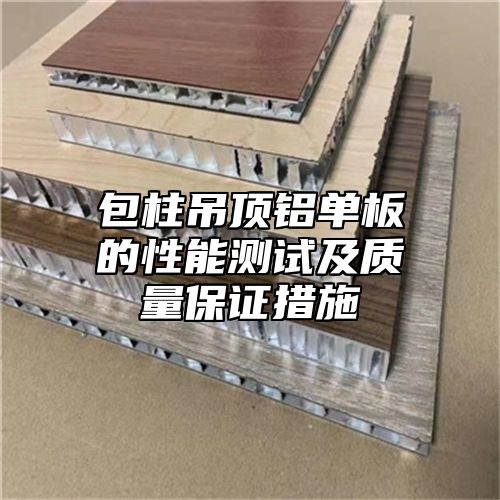

Performance testing and quality assurance measures of aluminum veneer for column suspended ceiling

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 9, 2025 00:33:40

- Click:0

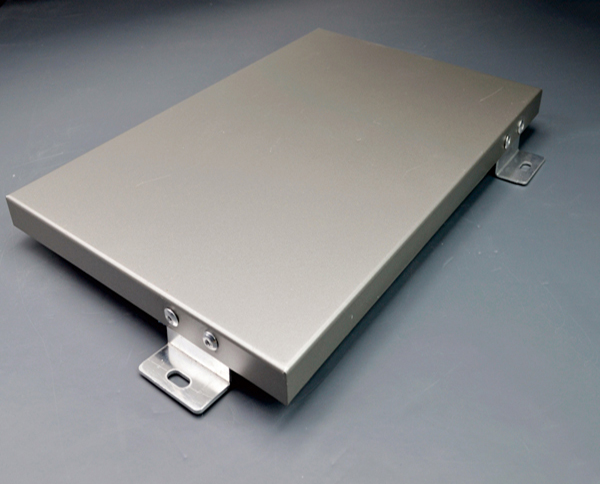

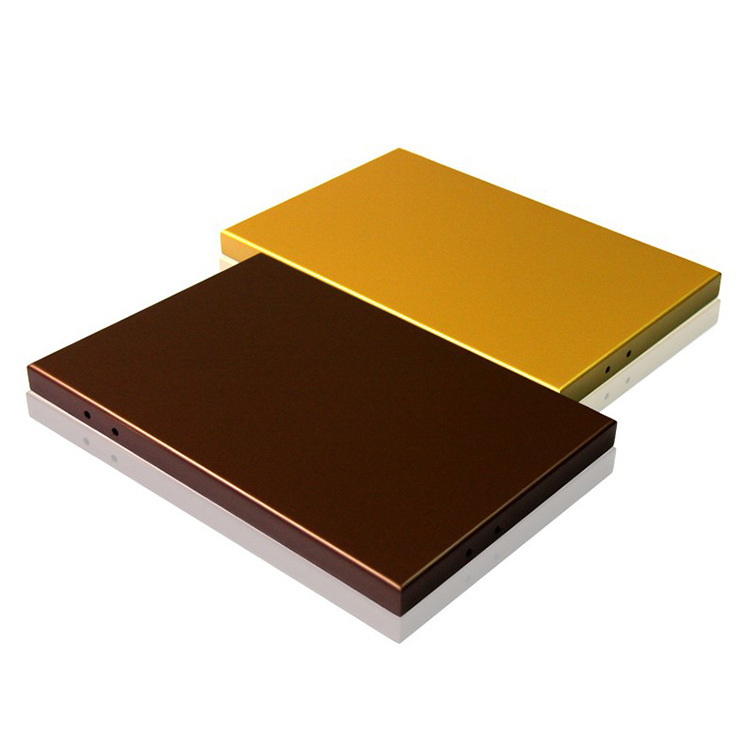

Aluminum veneer for column suspended ceiling is a high-end decorative material, and its performance and quality are the key to ensuring its effectiveness. Below, we will provide a detailed introduction to the performance testing and quality assurance measures of aluminum veneer for column suspended ceilings.

1、 Performance testing

1. Strength testing: The aluminum veneer of the column suspended ceiling needs to undergo strength testing to ensure that it can withstand certain weight and pressure. The commonly used testing methods include tensile testing, compression testing, etc.

2. Corrosion resistance test: The aluminum veneer of the column suspended ceiling needs to have excellent corrosion resistance to prevent oxidation and corrosion. The commonly used testing methods include acid salt spray test, alkaline salt spray test, etc.

3. Fire performance testing: The aluminum veneer of the column suspended ceiling needs to have very good fire performance to ensure the safety of people's lives and property. Common testing methods include UL94 fire rating testing, etc.

4. Sound insulation effect test: The aluminum veneer of the column suspended ceiling needs to have very good sound insulation effect to reduce the impact of noise on people. Common testing methods include sound insulation testing, etc.

2、 Quality assurance measures

1. Raw material selection: The quality of aluminum veneer for column suspended ceilings depends on the quality of the selected raw materials. Therefore, strict control is required during the production process, selecting high-quality aluminum alloy materials and conducting rigorous quality inspections.

2. Production process control: The production process of aluminum veneer for column suspended ceilings needs to be strictly carried out in accordance with standard operating procedures to ensure that each process meets the requirements and avoid quality problems.

3. Quality inspection: Multiple quality inspections are required during the production process to ensure that the product meets the required quality standards. A comprehensive inspection and testing of the finished product is also required to ensure that its performance and quality meet the standard requirements.

4. After sales service: After sales, it is necessary to provide comprehensive after-sales service, timely solve problems encountered by customers, and maintain and upkeep the product to extend its service life and aesthetics.

The performance testing and quality assurance measures of aluminum veneer for column suspended ceiling are very important. Only through scientific testing and strict quality control can the quality and performance of the product meet the standard requirements, providing people with a more comfortable and safe living environment.

Customer service QQ

Customer service QQ