Industry information

Company News

- Aluminum veneer customization, creating personalized space and new fashion!

- Aluminum alloy air conditioning cover, the secret weapon to protect summer coolness

- Composition and equipment of aluminum veneer production line

- Aluminum veneer: a delicate interpretation of architectural aesthetics

- Aluminum veneer, the fashionable "coat" of modern architecture

Industry dynamics

- Aluminum veneer: the fashionable choice for modern architecture?

- Aluminum curtain wall, the fashionable coat of modern architecture

- Aluminum curtain wall: the new favorite of fashion and environmental protection in modern architecture

- Aluminum veneer: the fashionable "coat" of modern architecture

- Aluminum curtain wall, the 'silver coat' of modern architecture

Frequently asked questions

- What is the production process of aluminum veneer?

- What will be the future innovation and development trend of aluminum veneer?

- What are the unique advantages and characteristics of aluminum veneer?

- What is the current supply and demand situation in the aluminum veneer market?

- What are the common styles and characteristics of the application of aluminum veneer in the home decoration industry?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Construction technology and quality control of perforated aluminum veneer for exterior walls

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 13, 2025 23:50:56

- Click:0

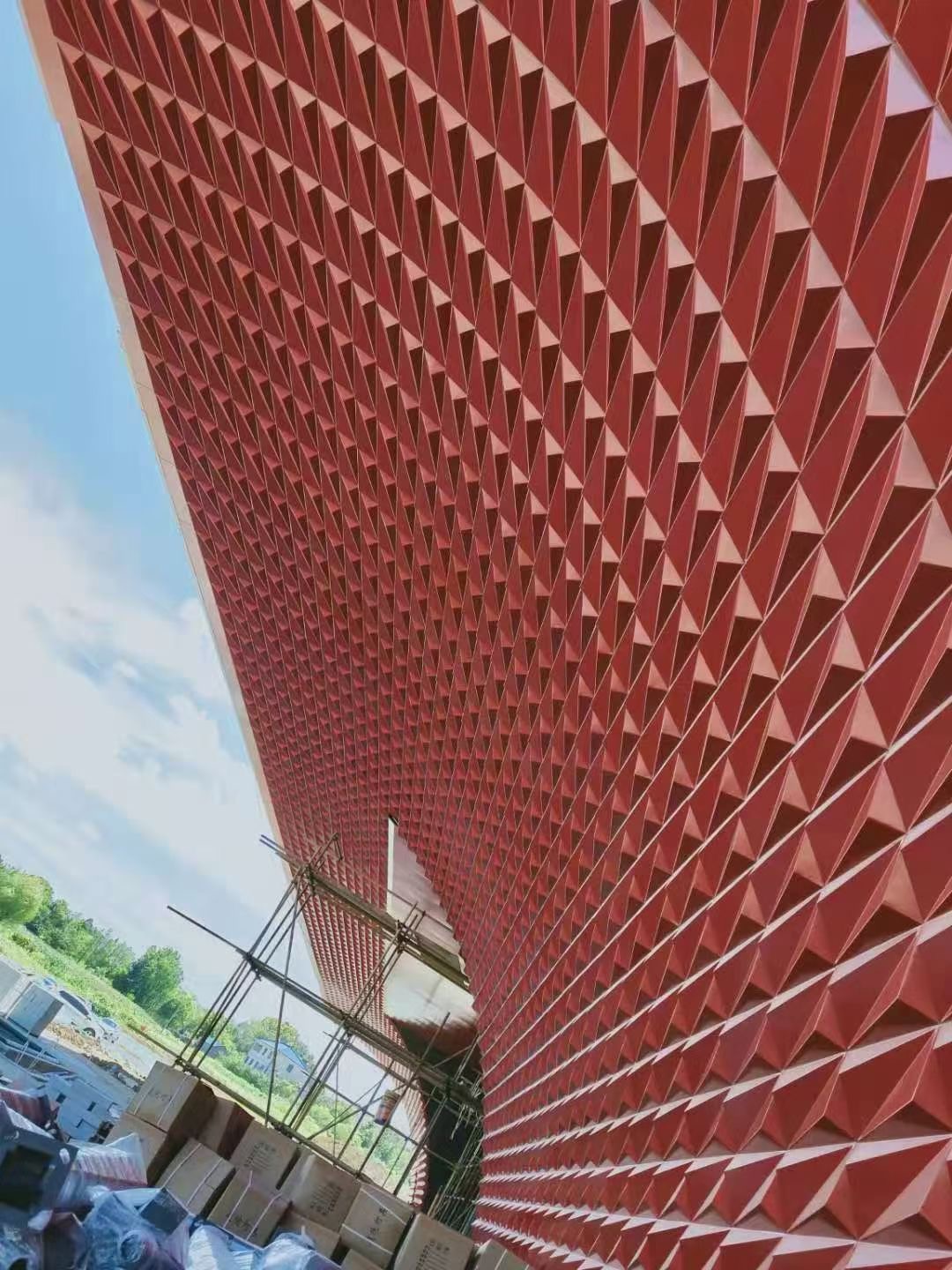

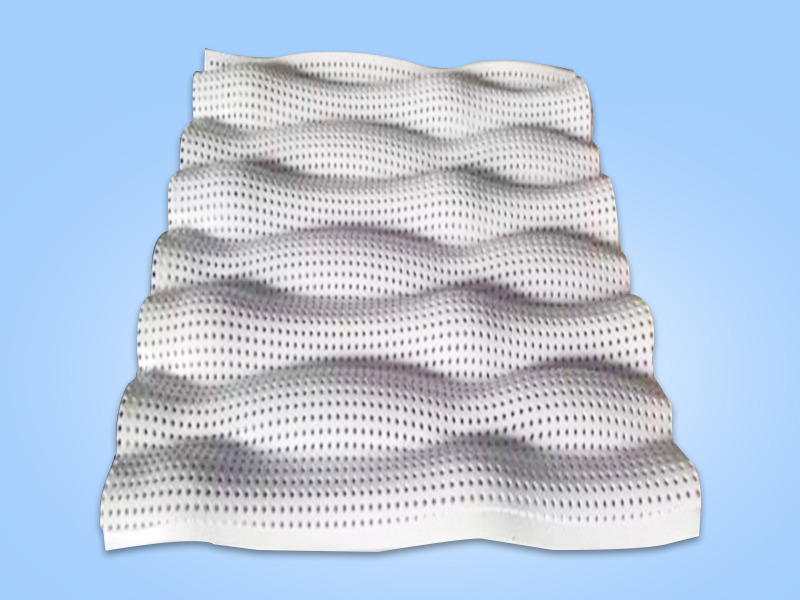

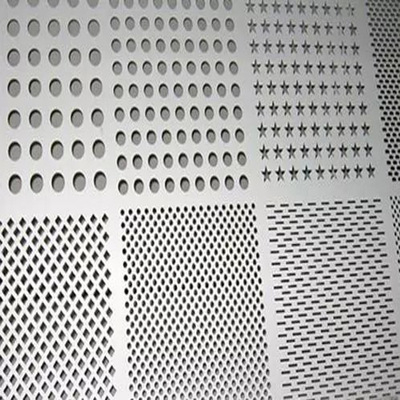

Perforated exterior aluminum veneer is a new type of building material that has the characteristics of lightweight, high strength, fire resistance, moisture resistance, sound insulation, and thermal insulation. It is widely used in commercial places, office spaces, hospitals and schools, residential areas, and other fields. During the construction process, proper craftsmanship and quality control are important guarantees for ensuring the quality of perforated exterior wall aluminum veneer. Below, we will provide a detailed introduction to the construction process and quality control of perforated aluminum veneer for exterior walls from several aspects.

1、 Preparation before construction

1. Measurement and laying out: Before construction, it is necessary to measure and lay out the building to determine the position and size of the perforated aluminum veneer on the exterior wall.

2. Material inspection: Prior to construction, it is necessary to inspect the perforated exterior aluminum veneer to ensure that it meets the design requirements and quality standards.

2、 Installation process

1. Keel installation: Firstly, the keel needs to be installed to support the structure of perforated aluminum veneer on the exterior wall.

2. Aluminum veneer installation: Then install the perforated exterior wall aluminum veneer onto the keel according to the design requirements, paying attention to maintaining its flatness and verticality.

3、 Quality control

1. Material quality control: When purchasing materials, strict quality control is required to ensure that they meet design requirements and national standards.

2. Construction process quality control: During the construction process, strict quality control is required for each link, such as measurement and laying out, aluminum veneer installation, etc., to ensure that it meets design requirements and national standards.

4、 Acceptance criteria

1. Appearance quality acceptance: Acceptance of the appearance quality of perforated exterior wall aluminum veneer, including surface flatness, color uniformity, and no obvious defects.

2. Structural quality acceptance: Acceptance of the structural quality of perforated exterior wall aluminum veneer, including whether the keel installation is firm, whether the aluminum veneer installation is flat, etc.

The correct construction process and strict quality control are important guarantees for ensuring the quality of perforated exterior wall aluminum veneer. During use, attention should be paid to pre construction preparation, installation techniques, and quality control to ensure good performance and safety. Only through reasonable construction methods and quality control measures can the advantages of perforated exterior aluminum panels be fully utilized to create a more comfortable and beautiful environment for people.

Customer service QQ

Customer service QQ