Corporate News

Company News

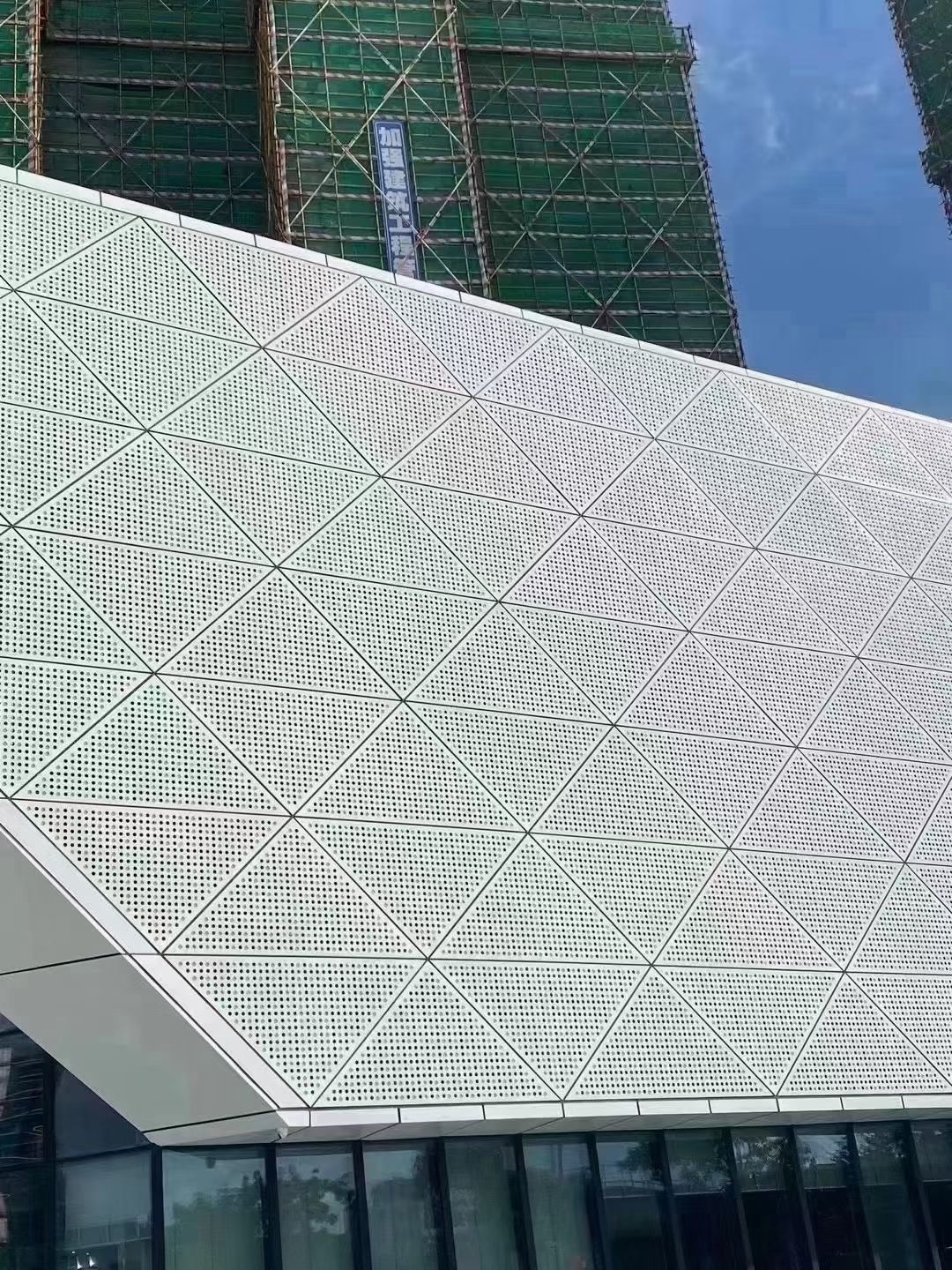

- Aluminum curtain wall, the fashionable choice in modern architecture

- Aluminum veneer: the "light and fashionable" choice for modern architecture

- Aluminum alloy air conditioning cover: a new favorite for heat dissipation and a fashionable choice for home use

- Aluminum alloy air conditioning cover: the guardian angel of coolness in summer

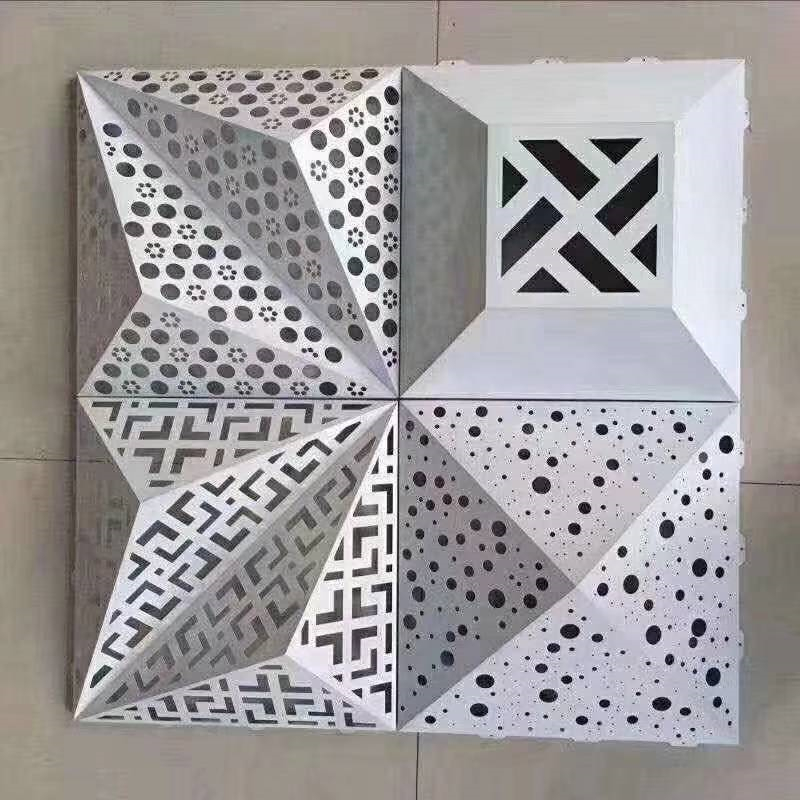

- Aluminum veneer customization, creating the art of personalized space

Industry dynamics

- Aluminum veneer: a fashionable choice in modern architecture

- Aluminum alloy air conditioning cover, the secret weapon to protect the coolness of summer!

- Aluminum curtain wall: a magnificent transformation of architectural art

- The characteristics and advantages of customized processing of aluminum veneer

- Aluminum alloy air conditioning cover: the guardian of coolness in summer

Frequently asked questions

- What is the current supply and demand situation in the aluminum veneer market?

- How to identify and select high-quality aluminum veneer?

- What will be the future innovation and development trend of aluminum veneer?

- What are the unique advantages and characteristics of aluminum veneer?

- What are the unique design and application advantages of aluminum veneer curtain walls?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Composition and equipment of aluminum veneer production line

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-15 19:57:35

- Click:0

Composition and equipment of aluminum veneer production line

Abstract: This article will provide a detailed introduction to the composition and equipment of an aluminum veneer production line. The aluminum veneer production line mainly includes four aspects: raw material processing, sheet production, coating processing, and inspection packaging. Each aspect has its specific equipment and process flow.

1、 Raw material processing

1. Aluminum plate cutting machine: used to cut raw aluminum plates into the required size.

2. Aluminum plate leveling machine: Level the cut aluminum plate to ensure a smooth surface.

3. Surface cleaning equipment: used to remove dirt and oxide layers from the surface of aluminum plates, improving surface quality.

2、 Board production

1. Aluminum plate rolling machine: Rolling cleaned aluminum plates to obtain the desired thickness and width.

2. Stretching machine: Stretching aluminum plates to enhance their strength and toughness.

3. Trimming machine: Trimming aluminum plates to eliminate unnecessary edges and ensure the aesthetic appearance of the board.

3、 Painting processing

1. Primer coating equipment: Apply the primer evenly on the surface of the aluminum plate to increase its weather resistance and coating adhesion.

2. Topcoat coating equipment: Use topcoat for final coating, giving aluminum veneer rich colors and textures.

3. Drying oven: used for drying and curing aluminum plates for coating, ensuring the stability and quality of the coating.

4、 Inspect packaging

1. Quality inspection equipment: including surface quality detectors, thickness measuring instruments, etc., used to check whether the quality of aluminum veneer meets the requirements.

2. Packaging machine: Packaging the produced aluminum veneer to protect its surface from damage.

3. Finished product palletizer: automatically stacks aluminum veneer finished products, improving work efficiency and storage space utilization.

5、 Summary:

The composition and equipment of the aluminum veneer production line cover four aspects: raw material processing, sheet production, coating processing, and inspection packaging. Each aspect has its specific equipment and process flow, and the collaboration of these equipment enables the aluminum veneer production line to efficiently complete the production process from raw materials to final products.

By providing a detailed explanation of the composition and equipment of the aluminum veneer production line in this article, readers can better understand the entire process of aluminum veneer production and gain insight into the key equipment involved.

- previous page:Evaluation and selection of aluminum veneer suppliers

- Next page:Recycling and reuse of aluminum veneer

Customer service QQ

Customer service QQ