Industry information

Company News

- The Fantasy Journey of Aluminum Veneer: One Board, One World

- Aluminum veneer: a fashionable choice for modern architecture and a new trend in environmentally friendly building materials!

- Aluminum alloy air conditioning cover: the guardian of coolness in summer homes

- Aluminum veneer: a lightweight interpretation of industrial aesthetics

- Aluminum veneer customization: the "outerwear" of personalized architecture

Industry dynamics

- Aluminum veneer customization, creating a new choice for personalized space!

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum Curtain Wall: The Gorgeous Coat of Modern Architecture

- Aluminum alloy air conditioning cover: the secret weapon of the guardian of coolness

- Aluminum curtain wall: the fashionable coat of modern architecture, revealing its charm!

Frequently asked questions

- What are the unique design and application advantages of aluminum veneer curtain walls?

- What is the current supply and demand situation in the aluminum veneer market?

- What is the production cost of aluminum veneer? What is the price?

- What are the different types of aluminum veneer production processes and their respective characteristics?

- What will be the future innovation and development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and quality standards of 1.5mm painted aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 22, 2025 11:14:00

- Click:0

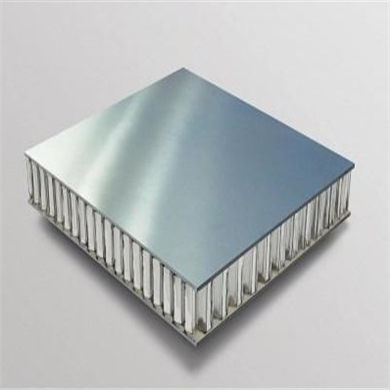

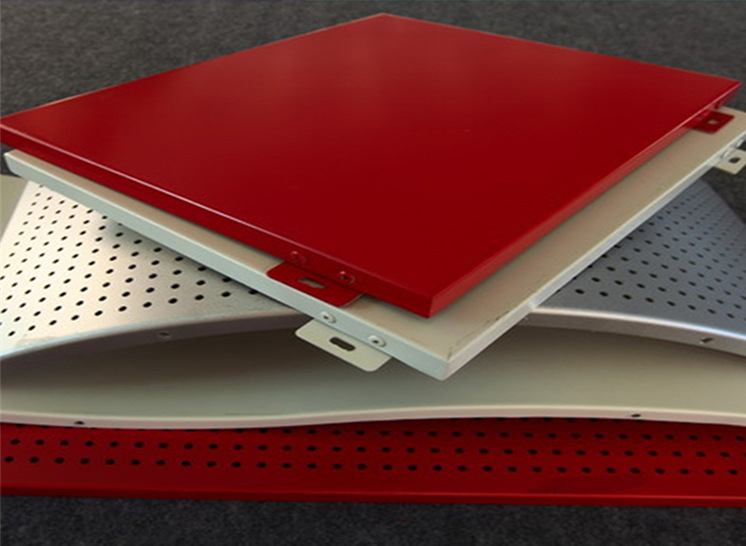

Painted aluminum veneer is a common building decoration material, while 1.5mm baked aluminum veneer has higher requirements in terms of production technology and quality standards.

1、 Production process

The production process of 1.5mm painted aluminum veneer mainly includes raw material preparation, leveling, cutting, bending, punching, drilling, welding and other links. The selection of raw materials and processing accuracy are one of the key factors affecting product quality. Generally speaking, high-quality aluminum alloy sheets should be selected as raw materials for 1.5mm painted aluminum veneer, and undergo strict testing and screening to ensure that they meet relevant quality standards. During the processing, high-precision equipment and technology are required to ensure the dimensional accuracy and surface smoothness of the product.

2、 Quality standards

The quality standards for 1.5mm painted aluminum veneer mainly include appearance quality, dimensional accuracy, surface smoothness, strength, and other aspects. Appearance quality is one of the important indicators for evaluating the aesthetic degree of a product, requiring a smooth surface, no obvious scratches, dents or other defects; High dimensional accuracy is required, generally controlled within ± 0.1mm; The surface smoothness requirement is high, generally reaching over 90%; In terms of strength, it should comply with relevant strength standards to ensure that the product will not deform or be damaged during use.

3、 Production process control

In order to ensure the stable and reliable quality of 1.5mm painted aluminum veneer, manufacturers need to establish a comprehensive production process control system. Specifically, we can start from the following aspects: establishing strict raw material procurement and inspection systems to ensure that the quality of raw materials meets requirements; Strengthen the maintenance and management of production equipment to ensure its normal operation; Again, strengthen the monitoring and control of the production process, and promptly identify and solve problems in production; Establish a sound product quality management system, conduct comprehensive testing and evaluation of products, and ensure that they meet relevant quality standards.

4、 Future Development Trends

With the increasing demand for building decoration materials, 1.5mm painted aluminum veneer as a new type of building material will be widely used and developed. In the future, manufacturers need to continuously improve their production processes and technologies, enhance product quality and performance, in order to meet market demands and customer expectations. It is also necessary to strengthen communication and cooperation with customers, understand their needs and feedback, continuously optimize products and services, and enhance the competitiveness and development potential of the enterprise.

Customer service QQ

Customer service QQ