Industry information

Company News

- Aluminum alloy air conditioning cover: the secret weapon to protect the coolness of home!

- Aluminum alloy air conditioning cover, the secret weapon to protect summer coolness!

- Aluminum veneer: the 'invisible hero' of modern architecture

- Customized aluminum veneer to create your own unique aesthetic space

- Aluminum veneer: the "lightweight elite" in modern architecture

Industry dynamics

- Aluminum veneer: the fashionable choice for modern architecture

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Aluminum Curtain Wall: A Modern Interpretation of Architectural Aesthetics

- Aluminum veneer: a fashionable choice in modern architecture

- Aluminum curtain wall: the "fashionable coat" of modern architecture

Frequently asked questions

- What is the production cost of aluminum veneer? What is the price?

- What will be the future innovation and development trend of aluminum veneer?

- What is the current supply and demand situation in the aluminum veneer market?

- What is the environmental performance of aluminum veneer? Does it meet the requirements of current sustainable development?

- What are the unique design and application advantages of aluminum veneer curtain walls?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the environmental requirements for punched aluminum veneer?

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 10, 2025 00:21:50

- Click:0

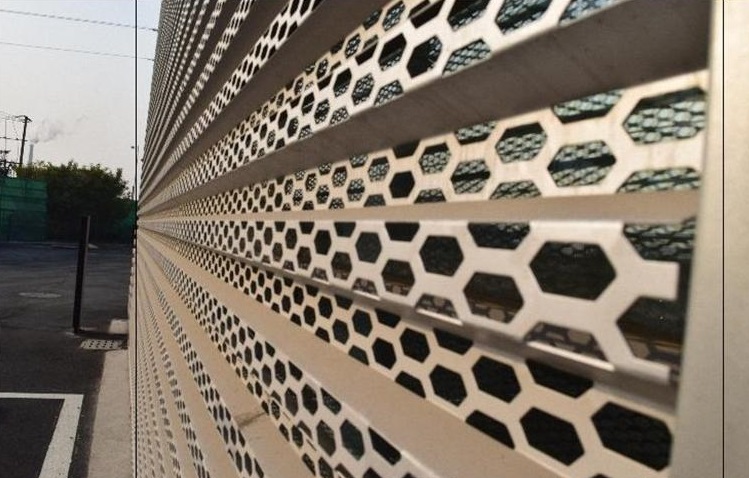

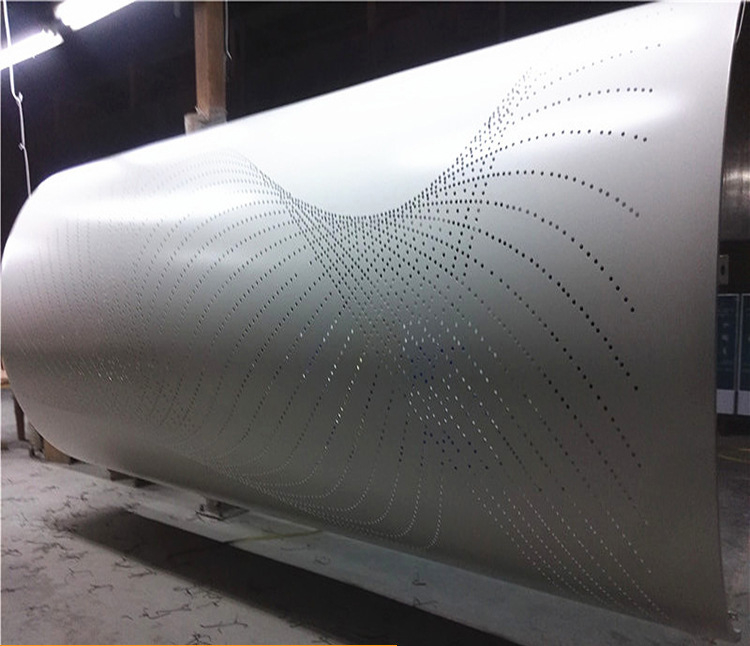

Punched aluminum veneer, as a widely used material in fields such as architectural decoration, advertising billboards, curtain walls, etc., its environmental standards are also an important aspect. The following will introduce the environmental standard requirements for punched aluminum veneer from the following aspects.

1. Environmental protection requirements for raw materials

The environmental performance of punched aluminum veneer first depends on whether the selected raw materials meet relevant environmental standards and requirements. During the production process, strict screening and testing of raw materials are required to ensure compliance with national or industry related environmental standards and quality indicators. It is also necessary to control and manage the production process to ensure that each link complies with relevant regulations and requirements.

1. Environmental protection requirements for surface treatment

The surface treatment method of punched aluminum veneer is also an important factor affecting its environmental performance. Generally speaking, punched aluminum veneers treated with anodizing, electrophoretic coating, and fluorocarbon spraying have good corrosion resistance and wear resistance, which can effectively resist the erosion of corrosive media such as acid and alkali, thus ensuring their environmental performance.

1. Environmental protection requirements for structural design

The structural design of punched aluminum veneer is also an important factor affecting its environmental performance. For example, measures such as inclined angle design and adding drainage channels can reduce the possibility of dust accumulation, thereby further improving the environmental performance of punched aluminum veneer. Reasonable structural design can also increase the transparency of perforated aluminum veneer, making indoor lighting softer and more comfortable, thereby reducing energy consumption.

1. How to improve the environmental performance of punched aluminum veneer

In order to improve the environmental performance of punched aluminum veneer, the following measures can be taken:

(1) Strengthen raw material quality management: Strengthen the screening and testing of raw materials to ensure that they meet national or industry related environmental standards and quality indicators.

(2) Optimizing surface treatment process: By optimizing the surface treatment process, the corrosion resistance and wear resistance of punched aluminum veneer can be improved, thereby enhancing its environmental performance.

(3) Strengthening structural design management: By enhancing the management and control of structural design, the transparency and ventilation characteristics of perforated aluminum veneer can be increased, thereby further improving its environmental performance.

The environmental performance of punched aluminum veneer is one of the important guarantees for its application effect and user experience. By strengthening the management of raw material quality, optimizing surface treatment processes, and enhancing structural design management, the environmental performance of punched aluminum veneer can be improved to meet the needs of different occasions.

Customer service QQ

Customer service QQ