Industry information

Company News

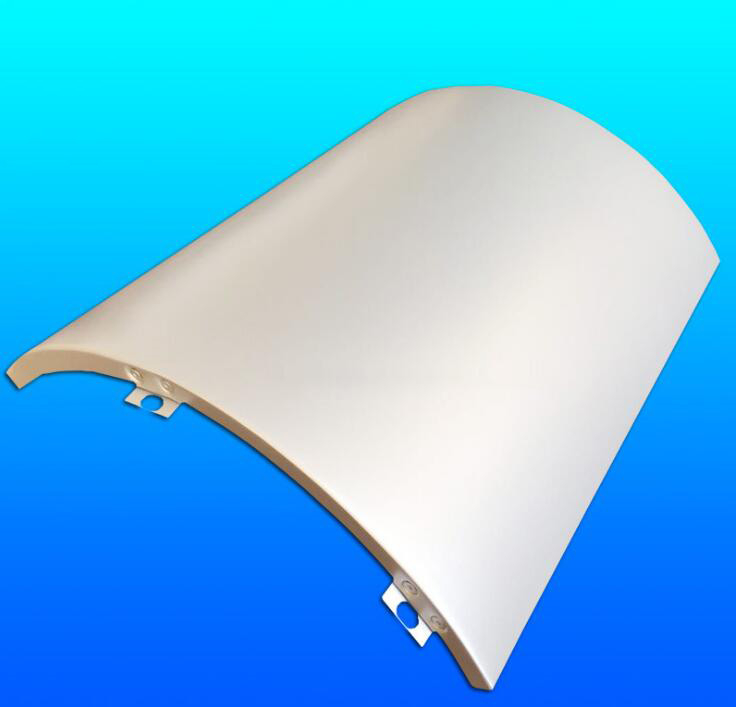

- Aluminum alloy air conditioning cover: the secret weapon to protect the coolness of summer!

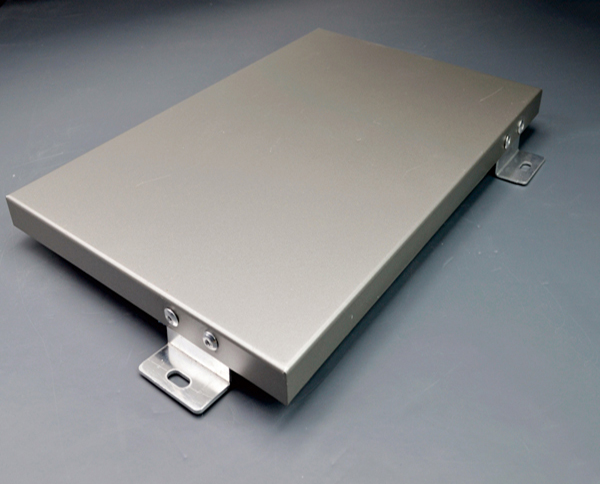

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating a new choice for personalized space!

- Aluminum curtain wall: the "fashionable coat" of modern architecture

- Aluminum air conditioning is the new guardian, starting a cool summer from "aluminum"!

Industry dynamics

- Introduction to the manufacturing process of 2.5mm fluorocarbon aluminum veneer

- Aluminum Curtain Jianghu: Light and Shadow Magicians in Modern Architecture

- Aluminum veneer customization: the art of creating personalized spaces

- Aluminum veneer: the secret weapon for creating a new style of modern architecture

- Aluminum cooling protection, new trend of air conditioning cover

Frequently asked questions

- What is the current supply and demand situation in the aluminum veneer market?

- What is the environmental performance of aluminum veneer? Does it meet the requirements of current sustainable development?

- What is the production process of aluminum veneer?

- What are the different types of aluminum veneer production processes and their respective characteristics?

- How to identify and select high-quality aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to control the oxidation treatment process of punched aluminum veneer?

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 9, 2025 01:45:08

- Click:0

Punched aluminum veneer, as a widely used material in fields such as architectural decoration, billboards, curtain walls, etc., its surface treatment method is also an important aspect. Oxidation treatment is one of the common surface treatment methods. The following will introduce how to control the oxidation treatment process of punched aluminum veneer from the following aspects.

1. Principle of oxidation treatment

Oxidation treatment is a surface treatment method that improves the corrosion resistance and wear resistance of punched aluminum veneer by forming a dense oxide film on its surface. Specifically, oxidation treatment is the use of chemical reactions to oxidize the surface of aluminum into a stable layer of oxide, forming a protective film to achieve the goal of protecting the aluminum surface.

1. Key points for controlling oxidation treatment process

In order to ensure the quality and effectiveness of the oxidation treatment of punched aluminum veneer, the following aspects need to be controlled:

(1) Temperature control: During the oxidation process, it is necessary to control the temperature well, usually between 200 ° C and 400 ° C. Excessive temperature can lead to thick oxide film, affecting the quality of punched aluminum veneer; If the temperature is too low, it will affect the oxidation reaction rate and prolong the processing time.

(2) Time control: The oxidation treatment time also needs to be carefully controlled, usually between 30 minutes and several hours. Excessive time can lead to thick oxide film, affecting the quality of punched aluminum veneer; If the time is too short, it will affect the oxidation reaction rate and lead to incomplete treatment.

(3) Concentration control: During oxidation treatment, it is necessary to control the concentration of the oxidant. Generally speaking, the higher the concentration, the faster the treatment speed, but at the same time, it will also increase the thickness of the oxide film. Therefore, adjustments need to be made according to the actual situation.

(4) Mixing speed control: During the oxidation treatment process, it is necessary to control the mixing speed well. Generally, a certain mixing speed needs to be maintained in order to allow the oxidant to fully contact the aluminum surface and promote the reaction. However, excessive stirring speed can also cause the oxide film to become too thick, so adjustments need to be made according to the actual situation.

1. How to improve the oxidation treatment effect

In order to improve the oxidation treatment effect of punched aluminum veneer, the following measures can be taken:

(1) Optimize process parameters: Adjust process parameters such as temperature, time, concentration, and stirring speed according to actual conditions to achieve the best oxidation treatment effect.

(2) Choose the appropriate oxidant: Choose the appropriate oxidant according to different application scenarios and requirements to achieve the best antioxidant and wear resistance.

(3) Strengthening post-processing: By enhancing subsequent processes such as cleaning, grinding, and polishing, the surface smoothness and flatness of punched aluminum veneer can be further improved, thereby enhancing its aesthetics and decorative effect.

Customer service QQ

Customer service QQ